HSMAdvisor

Advanced Feed And Speed Calculator for CNC Programmers and Machinists

Features in comparison with other S&F Calculators

| Feature | HSMAdvisor | HSMAdvisor Lite | FS Wizard: Mobile/Online | Competitor "G" |

| Basic Speeds and feeds |  |

|

|

|

| Constantly updated with the latest tools and materials. |  |

|

|

|

| Chip Thinning and HSM |  |

|

|

|

| Tool Life estimation |  |

|

|

|

| Full Tool length/deflection compensation |  |

|

|

|

| Flute length compensation |  |

|

|

|

| Show Tool Deflection |  |

|

|

|

|

Tool deflection limit (Breakage prevention) |

|

|

|

|

| Show Tool Torque |  |

|

|

|

| Tool Torque Limit (Breakage prevention) |

|

|

|

|

| Circular Interpolation compensation |  |

|

|

|

| Cut optimization |  |

|

|

|

| Tool Library |  |

|

|

|

| Advanced Tool Management(Keep track of stock, order tools, restock tools) |  |

|

|

|

| Machine Profiles |  |

|

|

|

| No Horse Power Limit |  |

* * |

|

|

| Spindle Power Curve compensation |  |

|

|

|

| Scientific calculator |  |

|

|

|

| Geometry calculators |  |

|

|

|

| Threads: 3 wire measurement |  |

|

|

|

| Reference: Tap/Drill charts, Fasteners, etc. |  |

|

|

|

| Application Wizard/Time Estimation |  |

|

|

|

| Payment/Usage type |

Flexible Licensing Options Unlimited Lifetime Floating -----OR----- Permanent License |

* 1 or 3 HP Lifetime Floating license |

Free for LITE version One time payment for life, Free with all HSMAdvisor Packages |

Fixed Licensing Option: Yearly and Lifetime subscription |

| Hardware and Software Requirements | PC, Windows XP/7/8/10 Microsoft .NET 4.0+ | PC, Windows XP/7/8/10 Microsoft .NET 4.0+ | Smartphone Android and iPhone |

PC, Mac. Requires |

| Regular Price for one seat |

From $195 Comes with Free FSWizard PRO Mobile app |

From $65 Comes with Free FSWizard PRO Mobile app |

$19 -----OR----- |

From $79 per year No mobile app available |

Legend:

|

Fully Supported Feature |

|

Unsupported Feature |

|

Partially Supported Feature |

Download your fully functioning free 30-day trial right now

ScreenShots and Features

|

|

|

♦ More than 200 different materials sorted into material groups according to SECO specifications ♦ A list of recently used materials saves time and effort ♦ Built-in search allows to filter out materials by a portion of their name

|

|

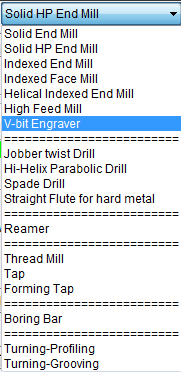

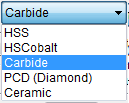

| ♦ A large number of milling, drilling, and turning tools are supported. ♦ Most modern cutting materials, coatings, and their combinations are available with a click of a mouse. ♦ The list includes such exotic tools as High-Feed and Helical Mills. |

|

|

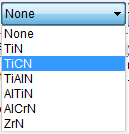

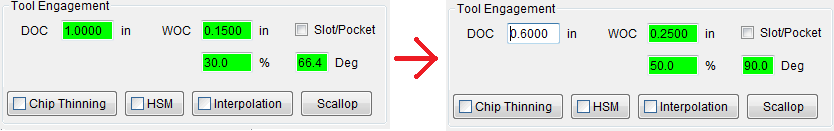

♦ Comprehensive cutter geometry that can be defined in either imperial or metric units ♦ Fields containing default or ideal values have a green background color, while fields with abnormal or exceeding limits values are red or yellow ♦ Suggested cutter engagement values like Depth of Cut (DOC) or Width of Cut (WOC) are directly related to cutter type, geometry, and workpiece material ♦ You can convert any field to "inch" or "metric" with a click of a mouse on the corresponding unit icon (in or mm) |

|

|

♦ Cutting Depth and Width are automatically calculated for each tool according to endmill geometry and material being cut. ♦ Change in either Depth or Width of Cut forces the other value to change accordingly to keep the load on the tool the same. ♦ Change in both values forces feed rate change. |

|

|

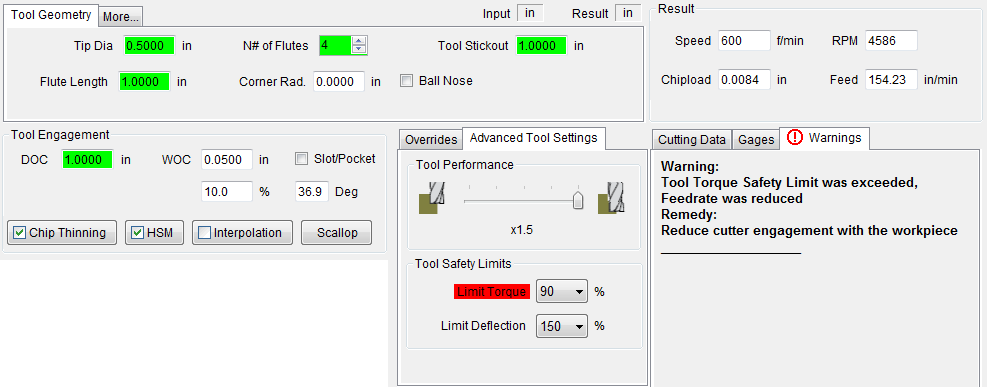

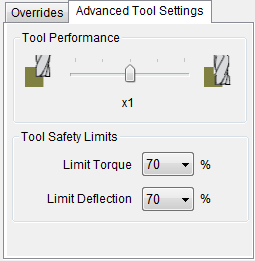

♦ While HSM (High-Speed Machining) techniques often put tooling and machinery on the edge of their capabilities, HSMAdvisor allows you to set maximum tool/machine loads to a comfortable for your case level. ♦ Whenever one or more safety levels are exceeded, a warning is triggered, pointing to the source of the problem and possible ways to fix it. ♦ Chip Thinning and HSM switches allow to account for reducing chip thickness as radial depth of cut is reduced below 30% of the cutter diameter. And maximize cutting speed and feed rate. ♦ To accommodate variations in the quality of tooling and machine rigidity, a Tool Performance slider was introduced. |

|

|

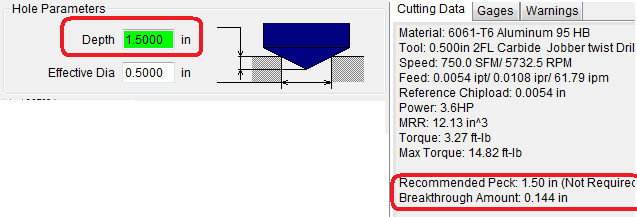

♦ Drilling tools come with the depth/effective diameter calculator ♦ Break-Thru and recommended pecking amount is listed for each drill type according to its tip and flute geometry. |

|

|

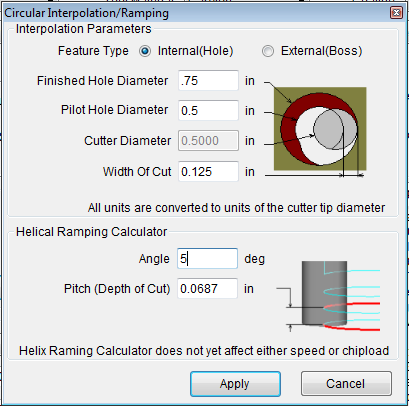

♦ Circular interpolation/ramping calculator adjusts cutting feed rate according to the geometry of the Hole or the Boss ♦ Helical Ramping Calculator allows calculating helix pitch and ramp angle quickly |

|

|

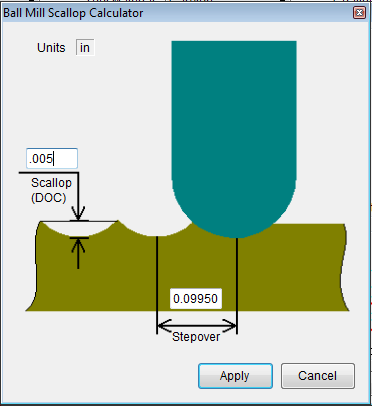

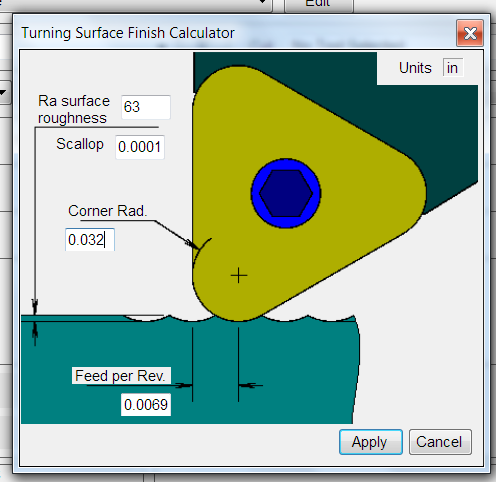

♦ Scallop calculator for Ball Nose End Mills quickly converts step-over to scallop height and vise-verse. ♦ Turning Surface Finish Calculator estimates and adjusts the feed rate to get the desired surface finish. |

|

|

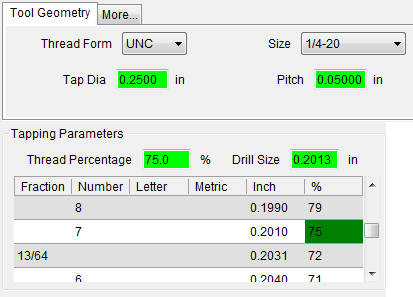

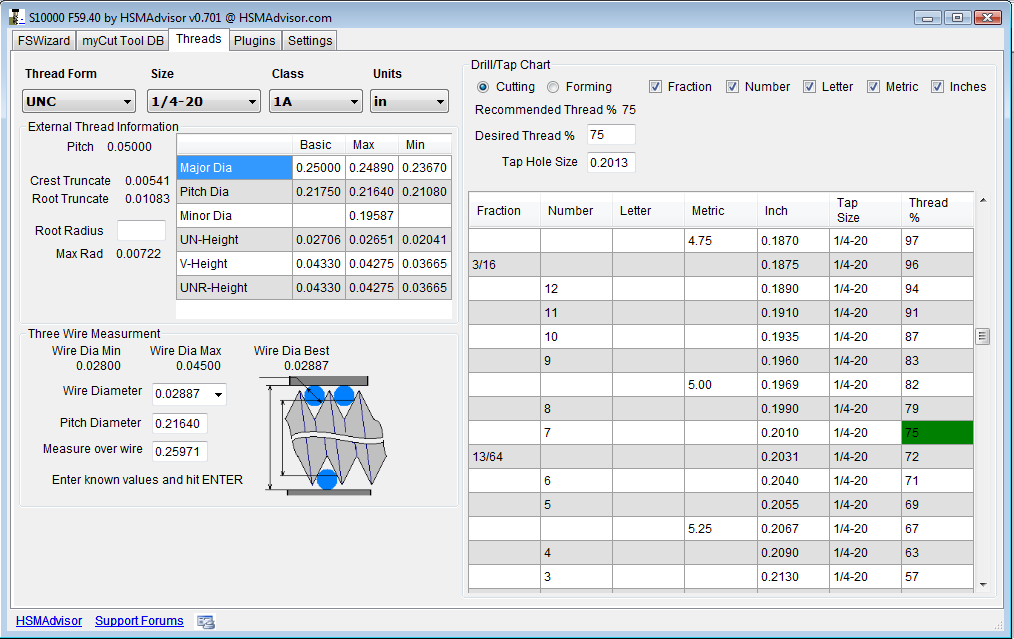

♦ Latest addition - tapping module specifies recommended drill size. ♦ A convenient table allows quickly finding a suitable substitute for any drill size in either imperial or metric. |

|

|

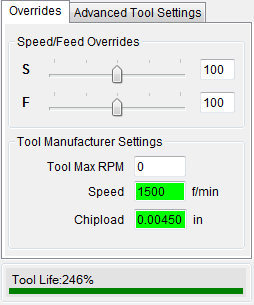

♦ Speed and Feed overrides help users fine-tune expected cutter life ♦ Tool Life indicator shows how tool life changes according to current cutting data ♦ Manufacturer Settings allow specifying exact recommended tool manufacturer cutting speed and chip load for each particular material. |

|

|

♦ Advanced tool settings allow changing aggressiveness of the cut and limit cutting forces to an acceptable level. |

|

|

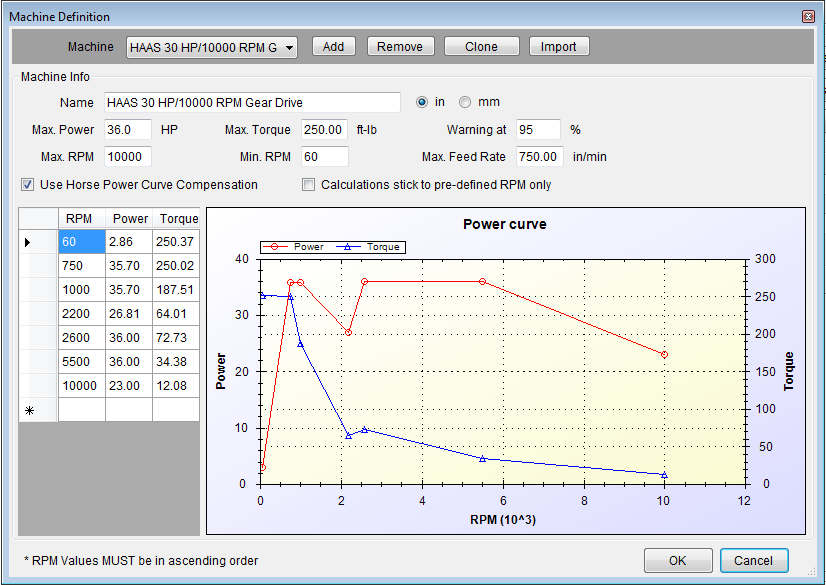

♦ Machine Spindle power output varies with RPM. ♦ Both belt drive and gearbox spindles are supported equally ♦ By checking the "Calculations stick to predefined RPM" box, the user can force calculated RPM to always round towards the closest RPM value from the power curve table. ♦ HSMAdvisor Cloud allows you to download and upload machines stored on the Internet. |

|

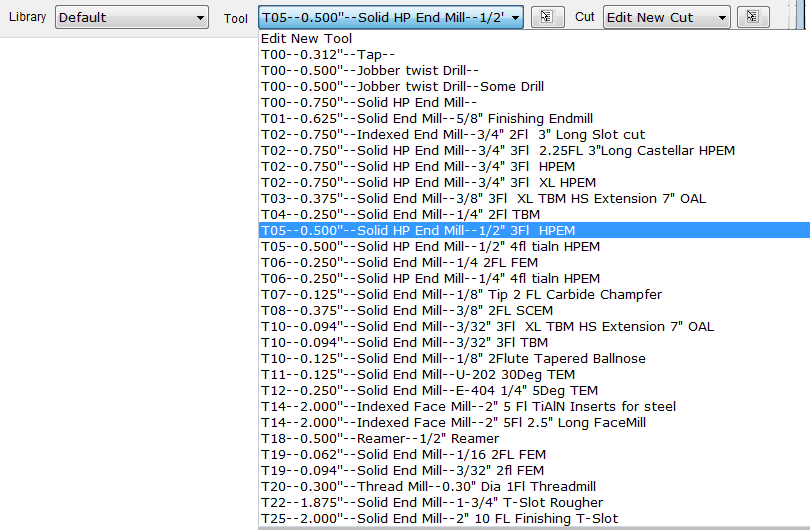

| ♦ You can save the Tool geometry into one of the multiple libraries for convenient re-use right when you need it. ♦ Some users choose to sort tools according to machine type. Others - according to material type being cut. |

|

|

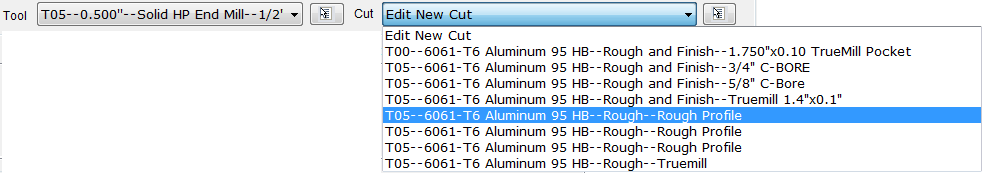

♦ Each saved tool entry can have an unlimited number of Cuts attached to it. ♦ The Cut is a workpiece-material-related data like Cutter Engagement and any possible overrides that affect cutting speed and chip load. |

|

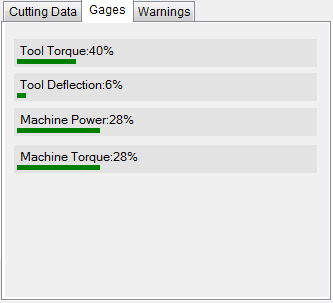

| ♦ The Gauges tab shows the most important cutting data at a glance. |

|

|

♦ Tool Database stores all tooling and associated cutting data in one place. ♦ Users can Copy, Move, Delete and Merge Libraries and tools alike. ♦ Using the "Actions" button, you can import and export Tool Libraries to and from HSMAdvisor for easy sharing and backup. ♦ Tool Database can be shared across several HSMAdvisor seats running on a network. ♦ Included Tool Management options allow to keep track of stock, create Purchase Requests and Re-stock tools. ♦ It will be possible to synchronize Local Database with online cloud storage at a later stage, allowing multiple programmers worldwide to have access to the same knowledge base. |

|

|

♦ Threads Tab shows specifications for major internal and external thread types. ♦ Three-wire measurement allows the use of both predefined and available wire sizes. ♦ It also lists Minimum, maximum, and Best wire size for each thread size and class. |

|

|

Various geometric calculators in the Reference tab ♦ Scientific Calculator ♦ Bolt Hole and Partial Bolt Hole Calculators ♦ Bolt Line Calculator ♦ Drill Point / Countersink Calculator

|

|

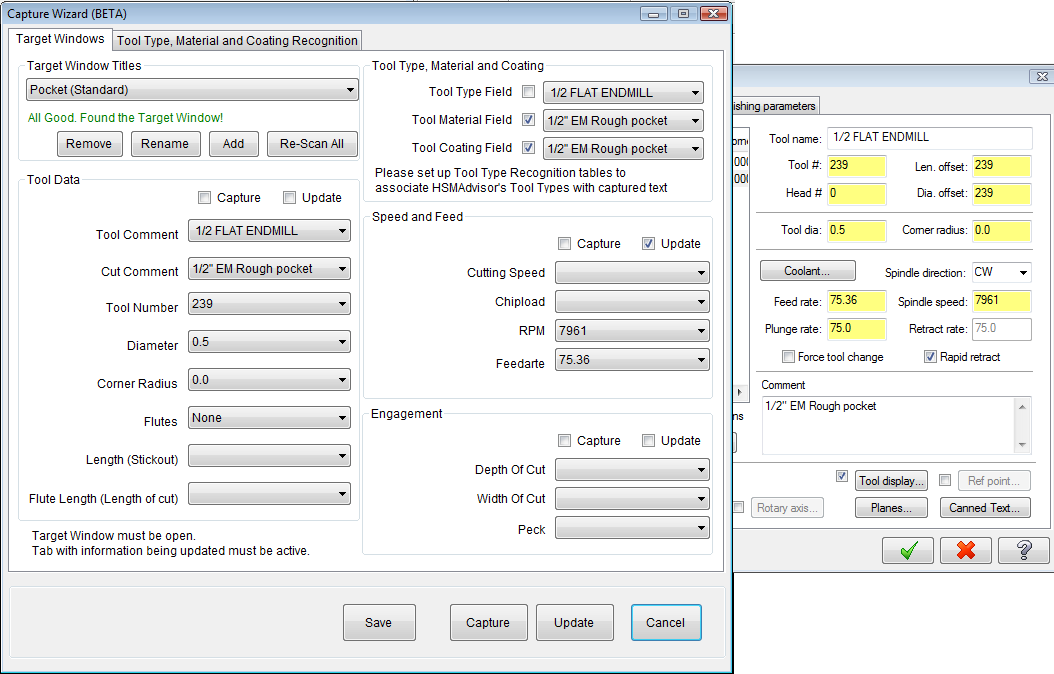

MasterCAM Integration

♦ Use a purpose-built hook to calculate cutting parameters for most milling and drilling tool-paths and tools ♦ Save cutting parameters into a database and recall them to apply saved parameters to new tool-paths quickly

|

|