Entering Cutting Tool Geometry

September 23, 2014, 8:09 pmArticle Summary

admin

September 23, 2014, 8:09 pm

admin

June 3, 2020, 6:22 pm

5123

Public

Author Summary

Sun January 25, 2026, 7:21 am

Sun January 25, 2026, 7:21 am

Enter Your cutting tool geometry starting with Tool Diameter (Turn diameter for Lathe)

All input fields displayed on the screen are important.

Normally when you change the tool type, default data is loaded from the database.

You can override this behavior in the Settings tab on the Fields and Limits that Reset to Default when Tool Type Changes panel by un-checking Reset Tool Data checkbox

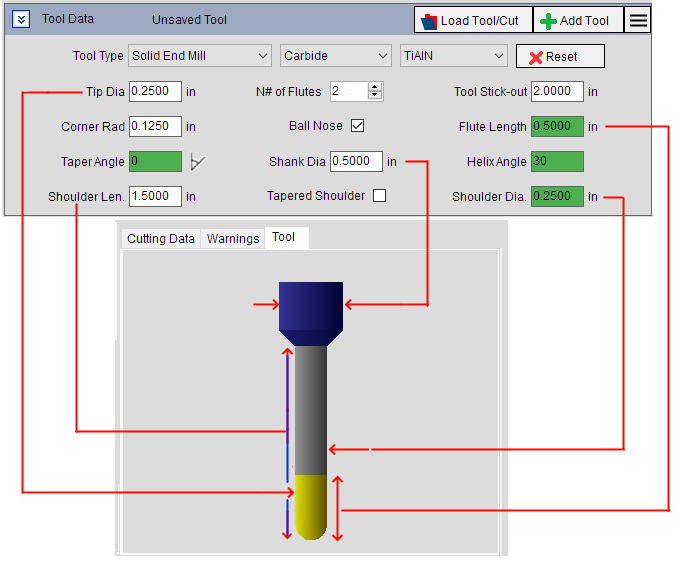

Here are the input fields available for Tool Geometry

-

Tip Dia (Mill, Drill)

The diameter of the cutting end of the end mill, drill, reamer etc

-

Turn Dia (Lathe)

The diameter of the finished workpiece.

When working in CSS and IPR mode it makes sense to keep Turn Dia equal to the actual maximum diameter of the workpiece. If you fail to do so, you may overload the spindle by calculating incorrect depth of cut and feed rate

-

N# of Flutes (Mill, Drill)

An effective number of cutting teeth on your milling or drilling tool.

-

N# of Inserts (Lathe, Boring Bar)

Effective number of cutting edges that do work at the same time. IE: some boring bars have 2 inserts

-

Tool Stickout

The distance from the nose of a tool holder to the tip of the cutting tool.

For integrated or arbor-mounted tooling, use the distance from the spindle nose to the tip of the tool.

-

Corner Radius

Corner Radius of the insert or the tip of the tool

-

Flute Length

Length of the cutting portion of the tool.

Be careful as some tool types like button cutters do not allow full-depth cuts. -

Lead Angle of the cutting edge.

The angle between the cutting edge and a plane perpendicular to the centerline of the toolCommon values for end mills

90: regular straight edge

45: Common angle for face cutters

5-30: High feed millsLower angles allow increased feed rates

-

Shank Dia

The diameter of the non-cutting portion of the tool -

Helix Angle

The helix angle of the flutes. -

Shoulder Length

The distance from the tip of the tool to the shank of the tool. It is often the same length as the Flute Length but is sometimes larger on necked tools. -

Tapered Shoulder

Controls how the shoulder portion is displayed and calculated. If it is checked, the shoulder is tapered from the end of the flutes to the beginning of the shank portion. - Shoulder Diameter

The diameter of the tool shoulder. It is often the same size as the Tip Diameter but is sometimes smaller for necked tools such as T-Slot cutters.

This is how the Tool Data Panel looks like for any End Mill Tool Type

Lines have been drawn to show which fields affect which tool features.

Drilling Tool Type Tool Data Panel

Turning Tool Type Tool Data Panel

Tap Tool type Tool Data Panel

Reamer, Counter Bore and Thread Mill Tool Type Tool Data Panel

See Also